Specification

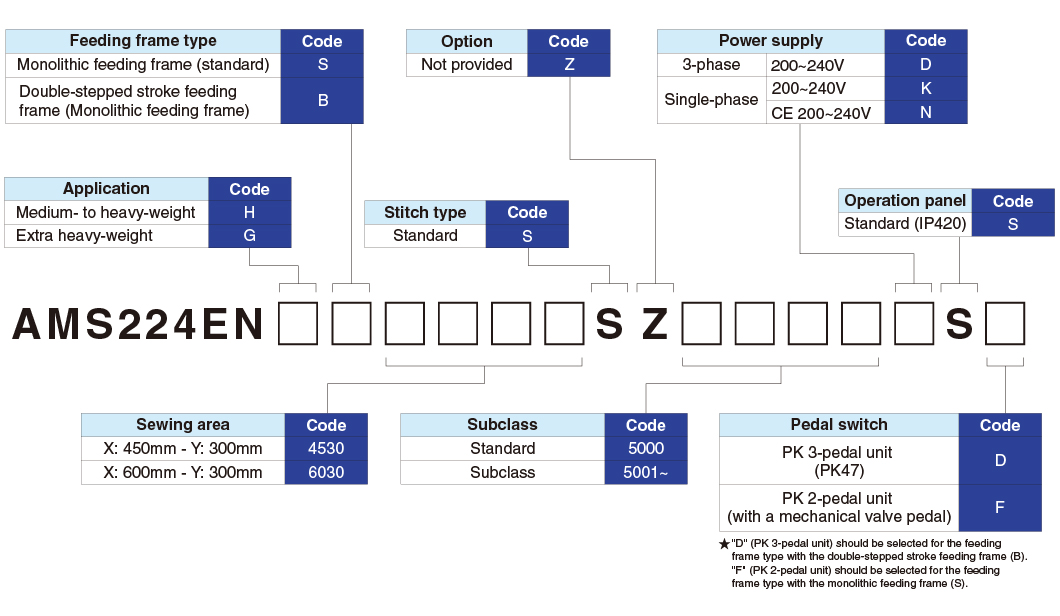

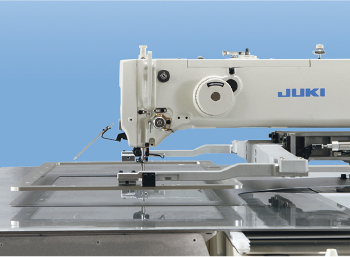

| Model name | AMS-224EN-HS4530 | AMS-224EN-GB4530 | AMS-224EN-HS6030 | AMS-224EN-GB6030 | ||

|---|---|---|---|---|---|---|

| Application | Medium-to heavy-weight | Extra heavy-weight | Medium-to heavy-weight | Extra heavy-weight | ||

| Feeding frame type | Monolithic feeding frame:(Pneumatic work clamp) | Double-stepped stroke feeding frame:(Pneumatioc work clamp) | Monolithic feeding frame:(Pneumatic work clamp) | Double-stepped stroke feeding frame:(Pneumatioc work clamp) | ||

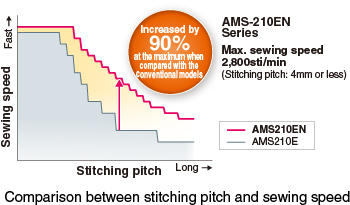

| Max. sewing speed | 2,500sti/min* (stitch length 3mm or less) | |||||

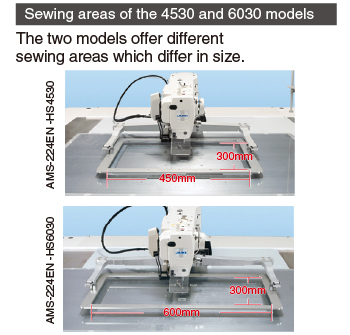

| Sewing area | 450mm (X) ×300mm (Y) | 600mm (X) ×300mm (Y) | ||||

| Settable stitch length | 0.1~12.7mm (0.05mm step) | |||||

| Needle bar stroke | 41.2mm | |||||

| Lift of the feeding frame | Max. 30mm | |||||

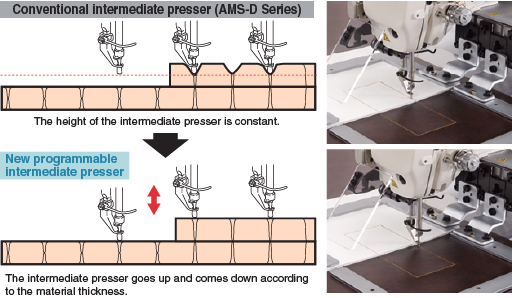

| Lift / Stroke of intermediate presser | Lifting amount : 20mm / Stroke : Standard 4mm (0~10mm) | |||||

| Variable lower position of the intermediate presser | Standard 0~3.5mm (max. 0~7.0mm) | |||||

| Change in height of the intermediate presser | Stepless control by programming (controlled by a stepping motor) | |||||

| Needle thread tension | Active tension (electronic thread tension control mechanism) | |||||

| Needle thread breakage detecting device | Provided as standard | |||||

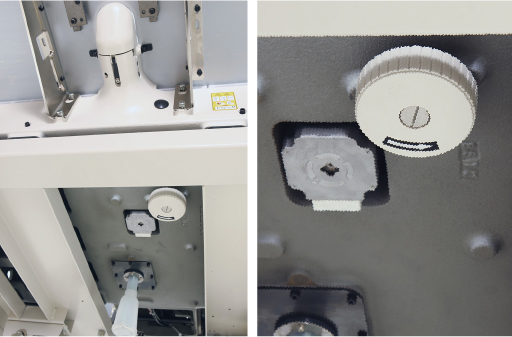

| Needle thread clamp | Stepping-motor driven clamping on the underside of the throat plate | |||||

| Prevention of the slip-off of thread at the beginning of sewing | Prevented by the needle thread clamp and active tension | |||||

| Thread trimming device | High-speed thread trimming mechanism driven by a stepping motor | |||||

| Needle (at the time of delivery) | DP×17 (#18) (135×17 Nm110) | DP×17 (#23) (135×17 Nm260) | DP×17 (#18) (135×17 Nm110) | DP×17 (#23) (135×17 Nm260) | ||

| Thread | #50~#2 | #20~#2 | #50~#2 | #20~#2 | ||

| Hook | Double-capacity shuttle hook | |||||

| Storage of pattern data in the memory | Main-body memory: Max. 500,000 stitches, 999 patterns (max. 50,000 stitches / pattern) | |||||

| External media: Max. 50,000,000 stitches, 999 patterns (max. 50,000 stitches / pattern) | ||||||

| Enlarging / Reducing facility | Pattern can be enlarged / reduced independently in the X and Y directions 1%~400% (0.1% step) | |||||

| Enlarging / Reducing system | Pattern enlargement / reduction can be done by increasing / decreasing either stitch length or the number of stitches (At the time of pattern selection, only the stitch length can be increased/decreased.) | |||||

| Bobbin thread counter Product counter | Up / Down system (0~9,999) | |||||

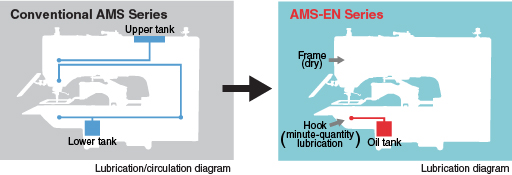

| Lubrication | The frame is lubricated with grease / The hook and hook driving shaft gear box are lubricated from a tank | |||||

| Lubricating oil | Hook: JUKI New Defrix Oil No.2 (equivalent to ISO VG32) | |||||

| Sewing machine motor | Compact AC servomotor (direct-drive system) | |||||

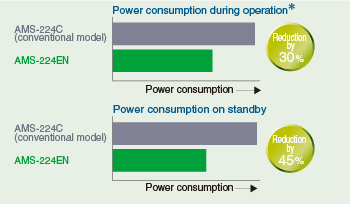

| Power requirement Power consumption | Single-phase, 3-phase 200~240V / 550VA | |||||

| Compressed air / Air consumption | 0.5~0.55MPa (Max. 0.55MPa) / 1.8dm³ / min (ANR) | |||||

| Total weight | 401kg | 410kg | ||||

| Dimensions | 1,703mm (W) ×1,370mm (D) ×1,200mm (H) (without thread stand) | 1,923mm (W) ×1,370mm (D) ×1,200mm (H) (without thread stand) | ||||

*”sti/min” stands for “Stitches per Minute.”

• For CompactFlash™, please use genuine JUKI products.

• “CompactFlash™”is a registered trademark of SanDisk Corporation, U.S.A.

• Microsoft Windows is a trademark of Microsoft Corporation, U.S.A., registered in the U.S.A. and other countries.

• Other company names and product names/brand names are trademarks or registered trademarks of the respective companies.

When you place orders