Short Thread

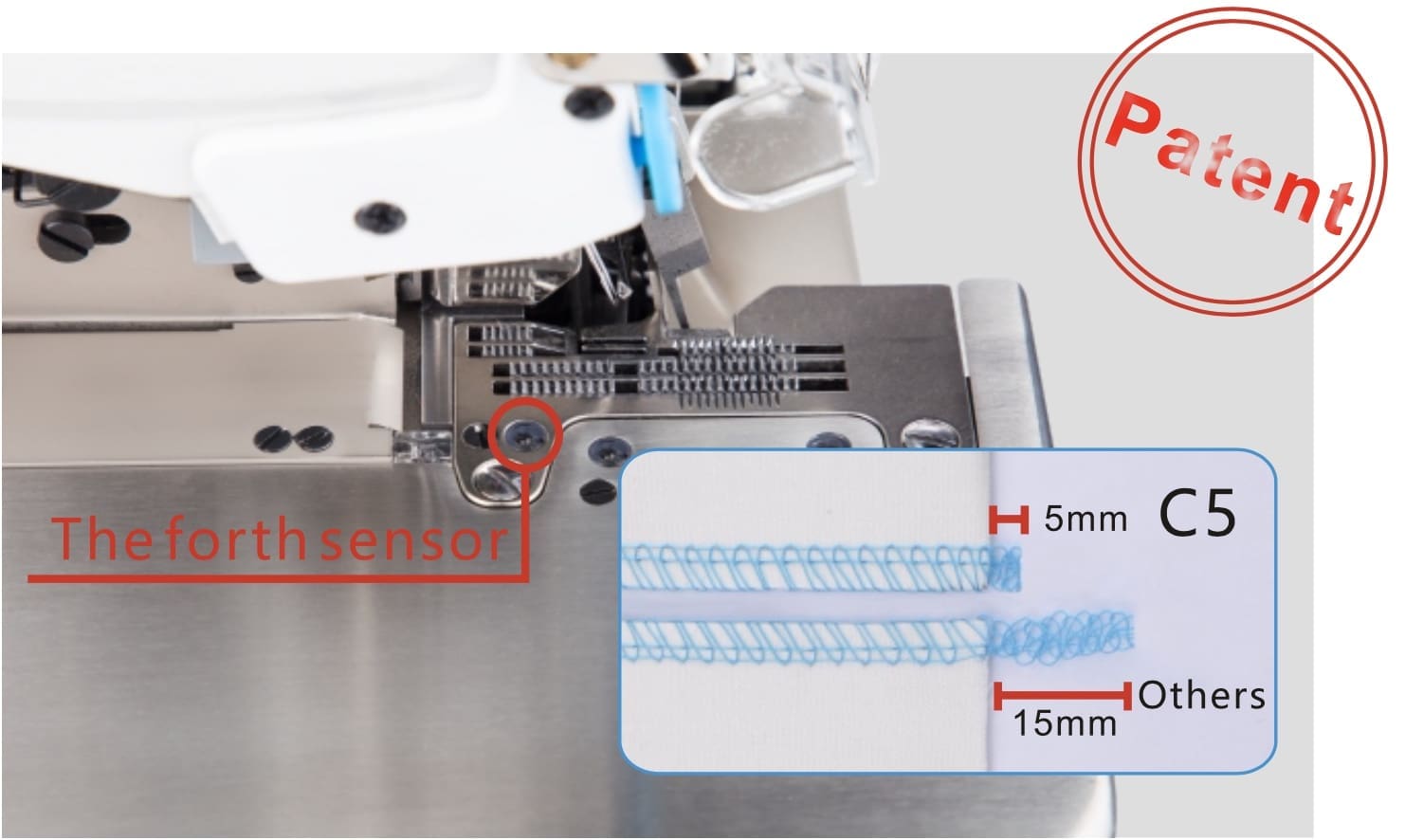

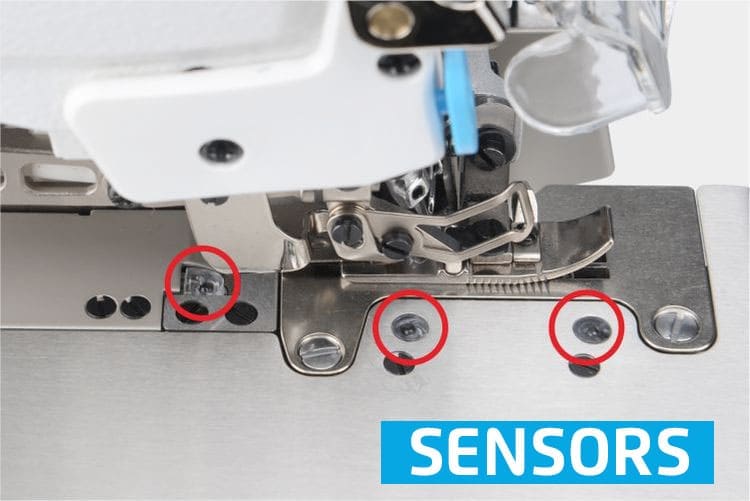

Thanks to the automatic electric cutter controlled by the photocells, the cut is 5mm both front and behind.

The front part sucks up the scraps of material, while the back part sucks up the cut threads and allows you to keep the seam clean.

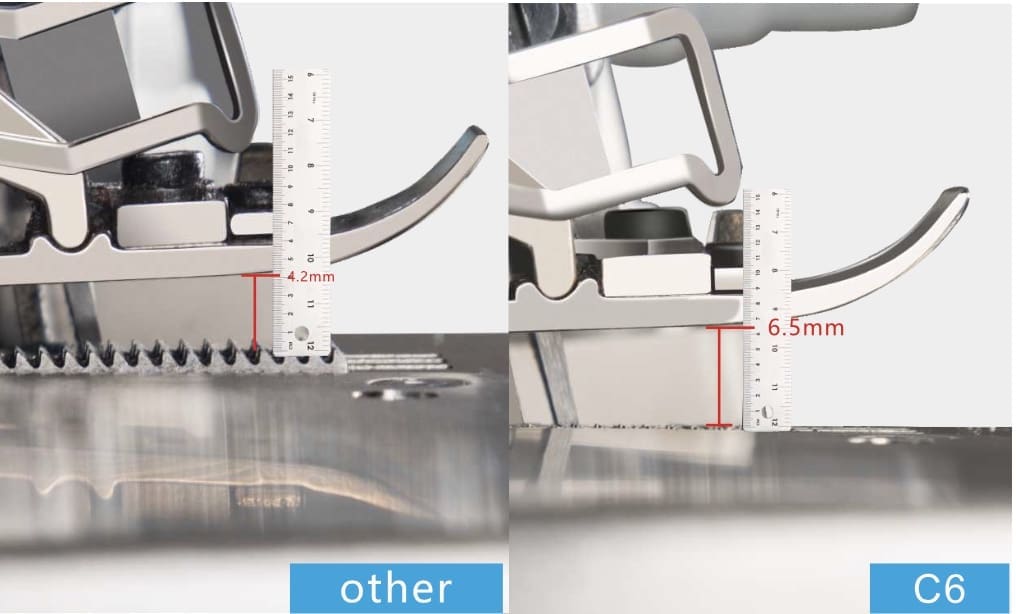

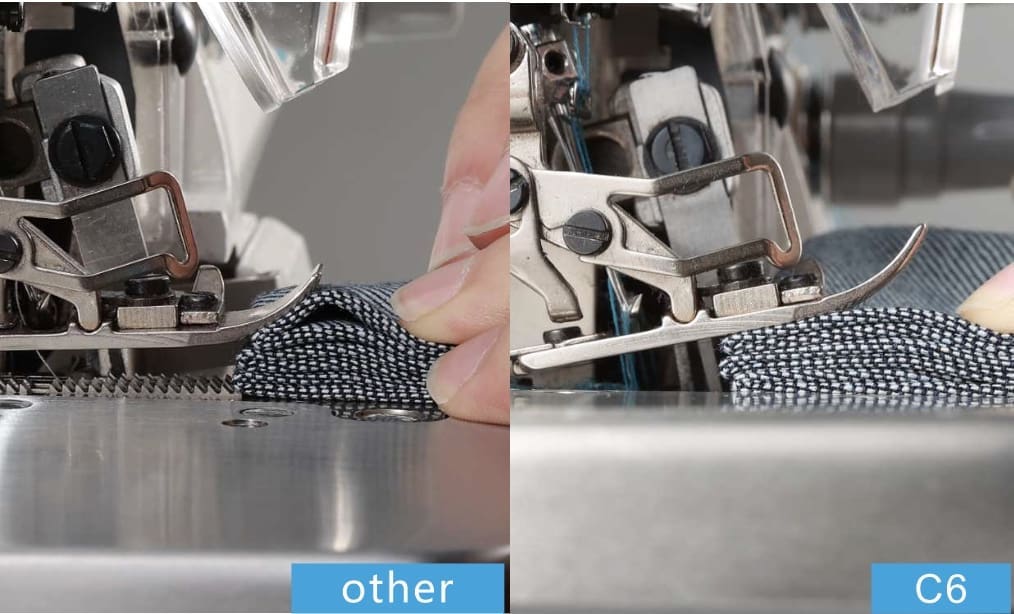

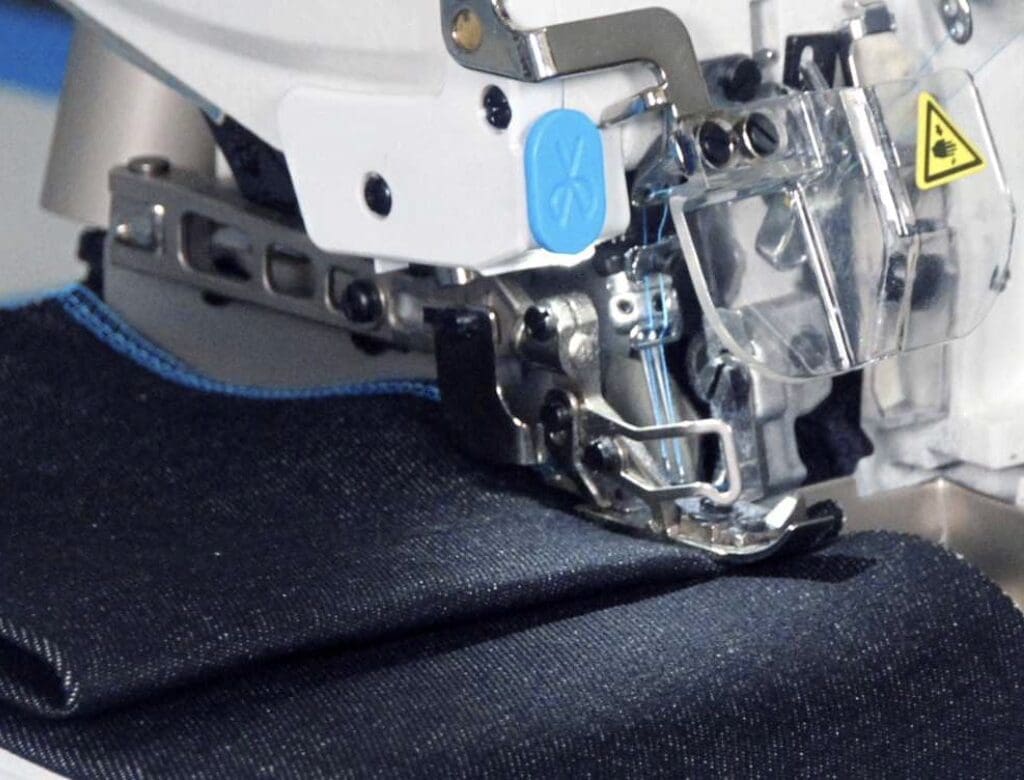

The space has been increased by 54% (from 4.2mm to 6.5mm). After the presser foot has been raised from the servo drive, the feed dog is lowered. You can place 8-12 layers of jeans while sewing without damaging or scratching them: the feed dog will automatically readjust during normal sewing.

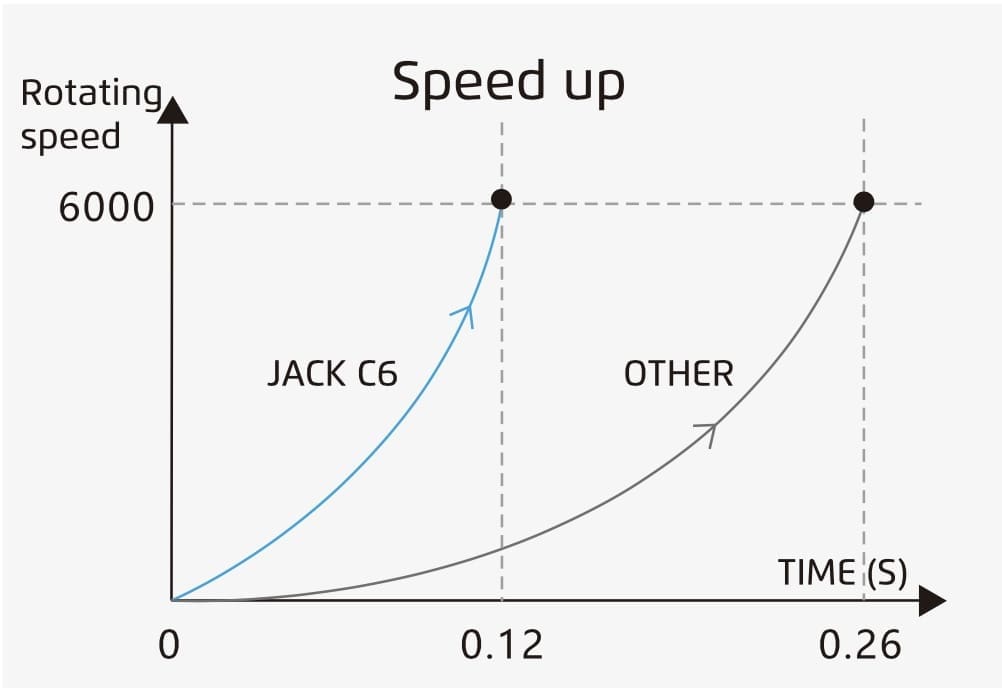

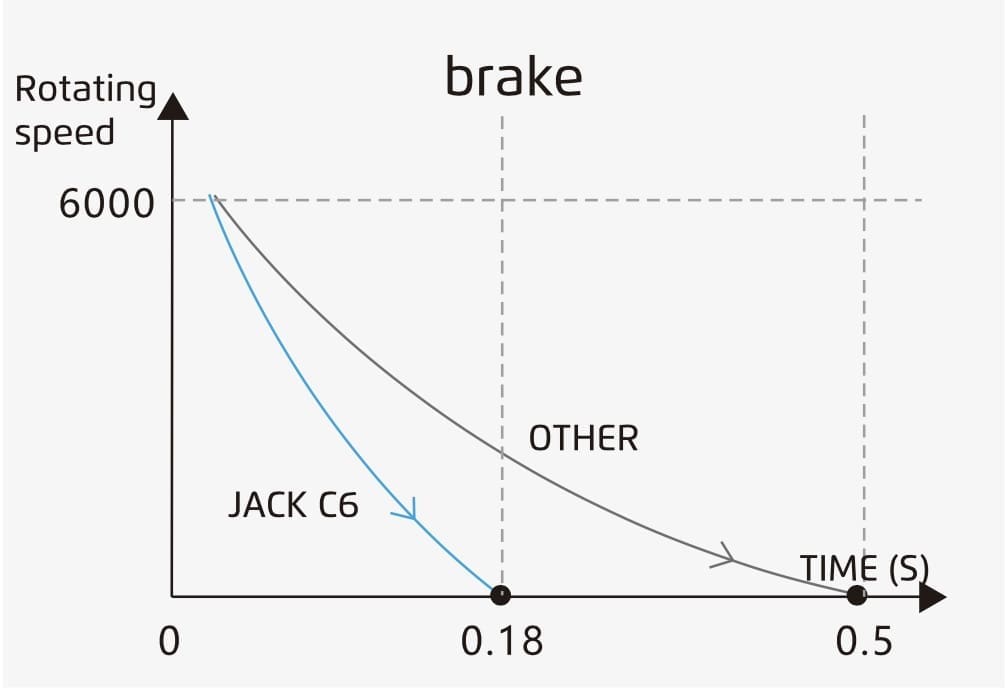

Efficienza aumentata del 35%. Response increased by 14.3%: acceleration from 0 to 6000rpm in 120ms.

Response increased by 14.3%: deceleration from 6000 rpm to 0 in 180ms.

Thanks to the automatic electric cutter controlled by the photocells, the cut is 5mm both front and behind.

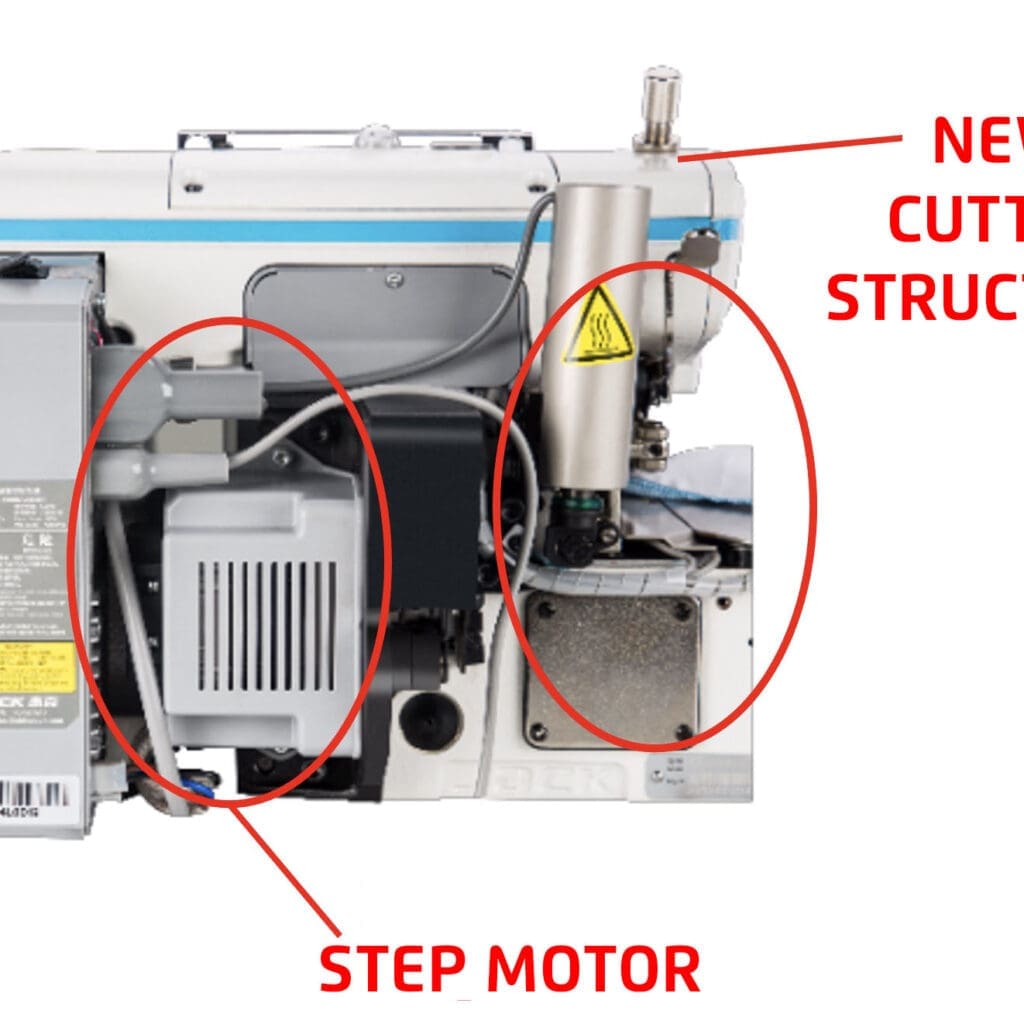

One button adjusts the presser foot lifter / feed dog height, without the need for tools or mechanical settings as driven by a controlled stepping motor conveniently from the digital display.

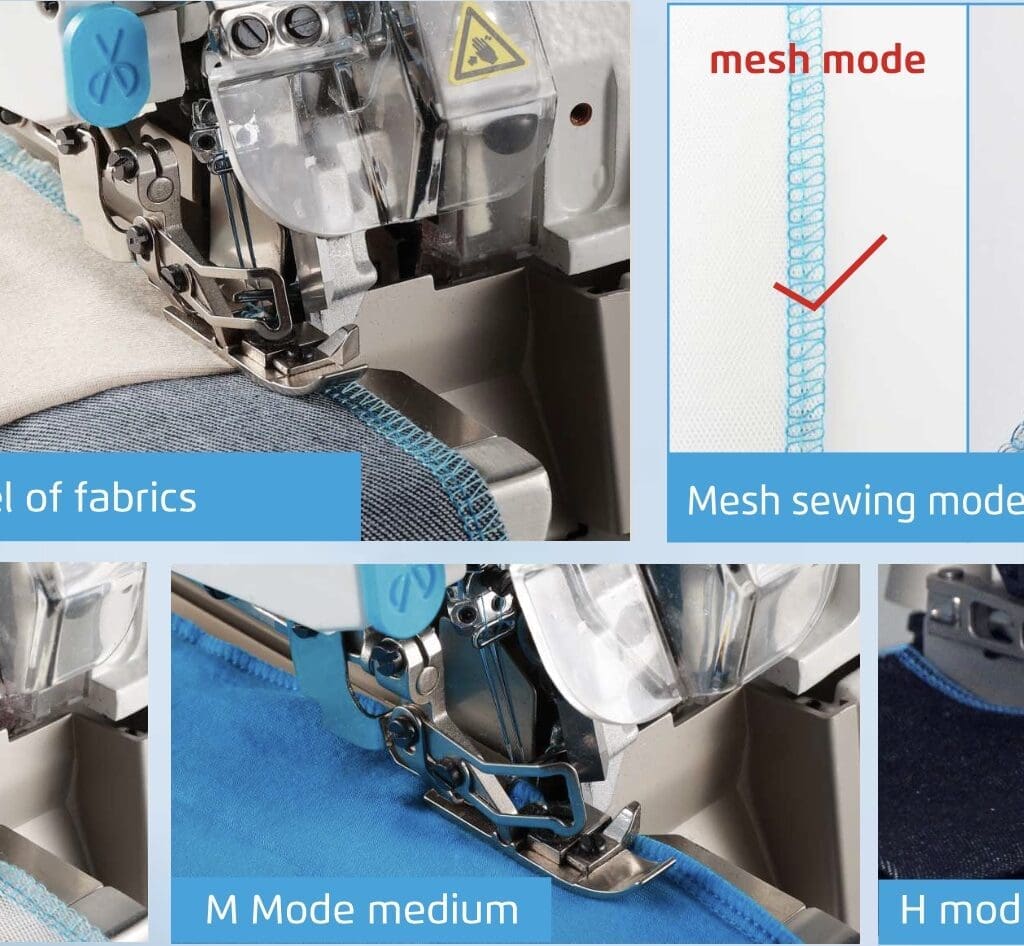

Intelligent recognition when sewing thicknesses with consequent automatic reduction of speed and strength increase, making the seam smoother.

With one click you can choose between light / medium / Heavy Duty material or have the machine do it independently.

Thanks to the step motors, we were able to reduce noise by guaranteeing 75dB at 6000rpm during sewing, 70dB during cutting and also during the lifting of the presser foot.

Learn the new functions thanks to the voice guide, otherwise you can only use it for errors and how to fix them, by clicking on the VOICE button.

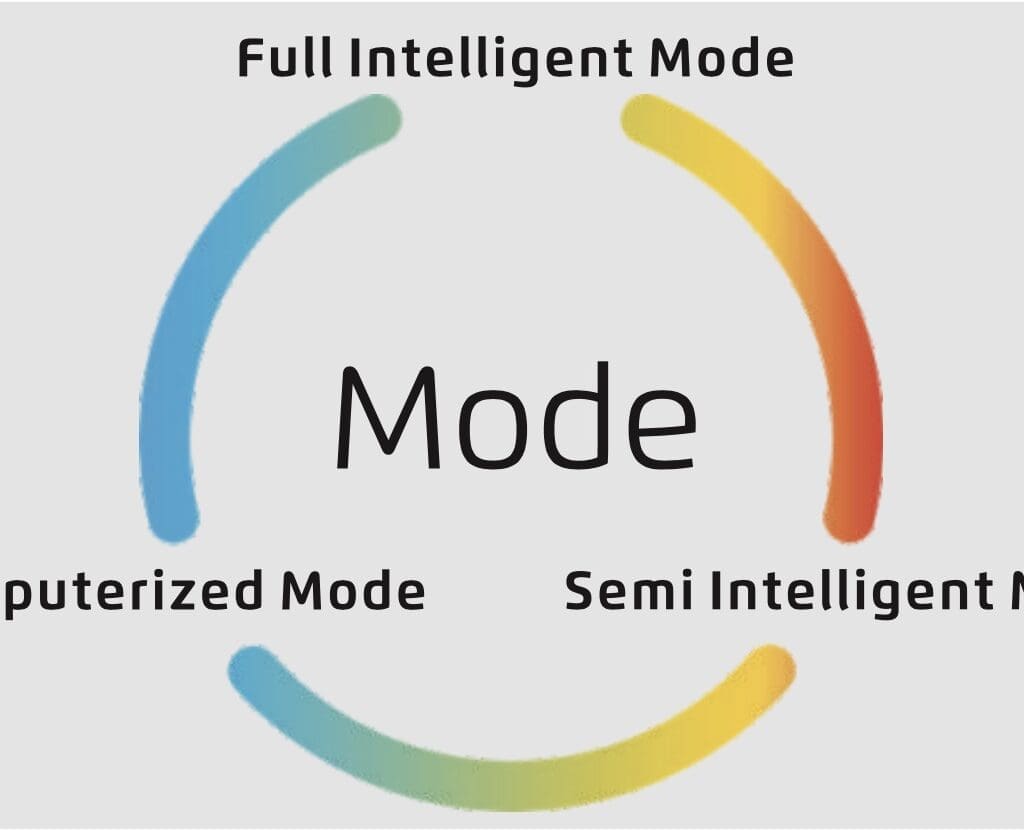

Manual with complete use of the pedal, semi-automatic with the use of the pedal while cutting and presser foot lifters are automatic thanks to the photocells and finally automatic where the machine works only with the photocells.

Used for automatic sewing and short cutting, they increase the precision and ease of use of the machine: making this machine affordable for everyone.