The sewing machine is a direct drive type in which a control box and an operation panel are integrated with the machine head.

The sewing machine is a direct drive type in which a control box and an operation panel are integrated with the machine head.

The machine achieves a practical maximum sewing speed of 7,000sti/min The MO-6800D/DD series are eliminated oil stains on the sewing product with “dry” technology.

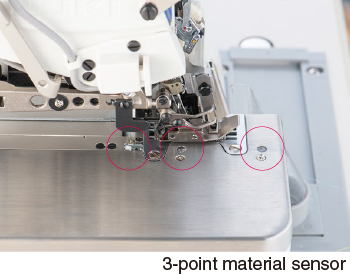

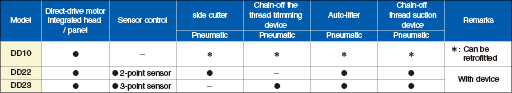

Automatic thread trimmer with a material sensor

The MO-6800S(D) / DD Series of sewing machine is provided as standard with the side cutter with 2-point material sensor (DD22) and Chain-off the thread trimming device with a 3-point material sensor (DD23).

Under the full-automatic mode, the material sensor detects the presence / absence of the material to prevent the operator from erroneously operate the side cutter etc. In addition to the full-automatic mode, the manual mode and the semi-automatic mode can be selected.

Operation panel and control box are integrated with the machine head

The energy-saving and highly efficient servomotor is installed in the direct-drive style. The sewing machine quick lystarts up and stops with increased accuracy, thereby demonstrating improved responsiveness.

USB port

The USB port is standard on the control panel and You can easily upgrade the software. The MO-6800S (D) / DD22, 23 has another one USB port for charging a smartphone, etc.

Operator fatigue reduction (LED light) Standard equipment with all series

For the LED light, the improved toning function with two additional colors (white / light bulb color) is provided. Illuminance of the LED light is adjustable in five levels. This LED light helps reduce the operator’s eye fatigue who is engaged in sewing work for a long time.

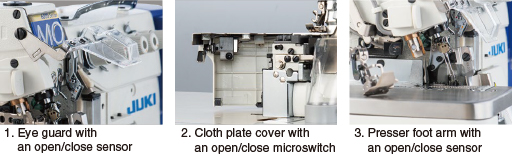

The cover sensor unit and cover microswitch unit

The cover sensor unit and cover microswitch unit that detect 1, 2 and 3 (shown right) are closed tightly during sewing, thereby preventing the sewing machine from starting up unexpectedly.

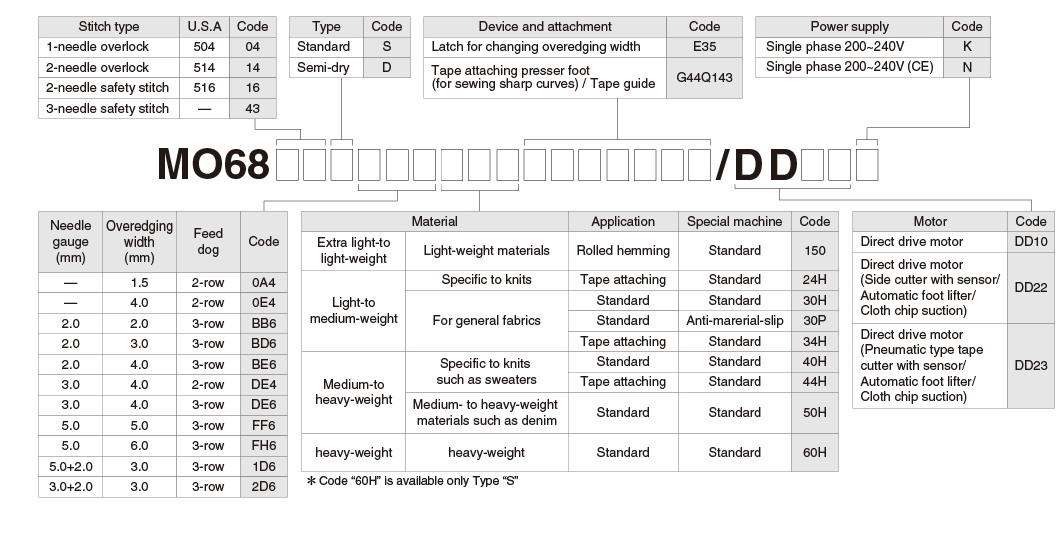

Specification

| Model name | MO-6800S/DD10, 22, 23 | MO-6800D/DD10, 22, 23 | ||||||

|---|---|---|---|---|---|---|---|---|

| MO-6804S | MO-6814S | MO-6816S | MO-6843S | MO-6804D | MO-6814D | MO-6816D | MO-6843D | |

| Stitch type | 1-needle overlock | 2-needle overlock | Safety stitching | 3-needle safety stitching | 1-needle overlock | 2-needle overlock | Safety stitching | 3-needle safety stitching |

| Stitch style in the U.S.A. | 504 | 514 | 516 | – | 504 | 514 | 516 | – |

| Dry type | – | – | – | – | Semi-dry | Semi-dry | Semi-dry | Semi-dry |

| Max. sewing speed | 7,000sti/min* | |||||||

| Stitch length | 0.6~3.8 (4.5)mm | |||||||

| Needle gauge (mm) | – | 2.0 | 3.0, 5.0 | 3.0+2.0, 5.0+2.0 | – | 2.0 | 3.0 | 5.0+2.0 |

| Overedging width (mm) | 1.5, 4.0 | 3.0, 4.0 | 4.0, 5.0, 6.0 | 3.0 | 4.0 | 2.0, 3.0, 4.0 | 4.0 | 3.0 |

| Bottom differential feed ratio | Gathering 1:2 (Max. 1:4), Stretching 1:0.7 (Max. 1:0.6) | |||||||

| Needle bar stroke | 24.5mm | |||||||

| Inclination angle of the needle | 20° | |||||||

| Needle mechanism | Lower bushing method | |||||||

| Needle | DCx27 (excluding some subclass model) | |||||||

| Max. lift of the presser foot | 7mm (excluding some subclass model) | |||||||

| Max. presser foot pressure | 63.7N (6.5kgf) | |||||||

| Stitch adjusting method | By push-button | |||||||

| Differential-feed adjusting method | By lever (with micro-adjustment) | |||||||

| Weight of the machine head | 27kg | |||||||

| Lubrication | Automatic (The needle bar mechanism and upper looper mechanism do not require lubrication.) | |||||||

| Lubricating oil | JUKI Machine Oil 18 (equivalent to ISO VG18) | |||||||

| Needle cooler | Provided as standard | |||||||

| Needle thread heat remover | Provided as standard | |||||||

| Micro-lifter | Option | |||||||

*sti/min is the abbreviation for “stitches per minute”

When you place orders