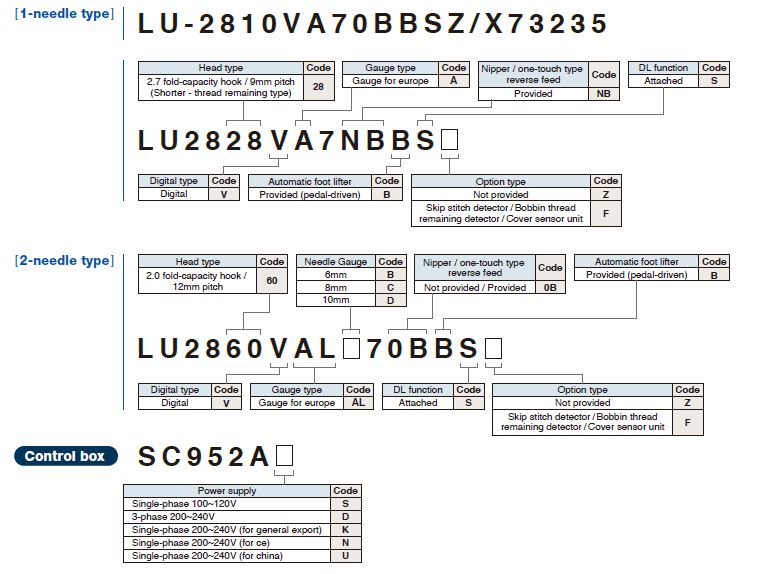

When you place orders

Inspire the Knowledge in Sewing Adjustment Epoch-making Sewing Systems in history.

Digital sewing system proposes the production process added with a computerized new value to all the people who engage in production.

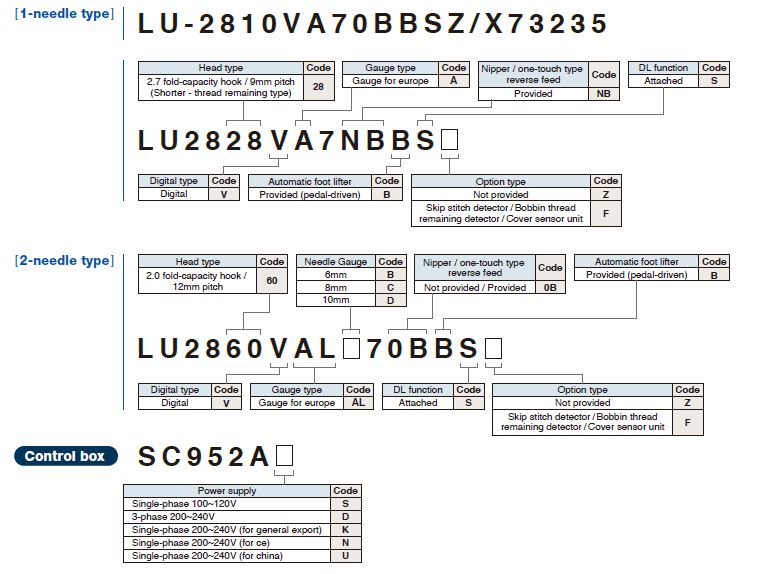

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially-available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data management and software update can be carried out with ease using a USB thumb drive.

Data items of sewing can be numerically managed to ensure “stable quality” and reduction in time required for setup changes. Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive.

Sewing conditions can be set easy since sewing conditions such as thread tension, stitch length, presser foot pressure, alternate vertical movement amount, etc. are displayed on one screen.

Automatic OFF function of the operation-panel backlight

The operation-panel light can be turned OFF after a lapse of the preset time.

Sleep mode (Automatic power-OFF function)

If no operation is carried out for a predetermined period of time, the power supplies to the motor, etc. can be automatically turned OFF.

*These options can be set up on the operation panel.

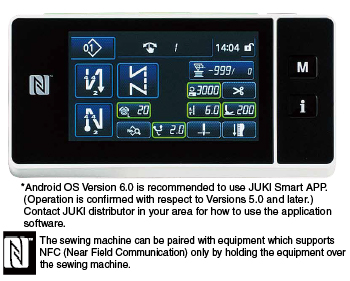

This device pulls the needle thread into the wrong side of the material at the beginning of sewing, thereby ensuring more beautifully-finished seams.

The shorter-thread remaining type LU-2828V-7 is a high-performance sewing machine.

It leaves a shorter thread on the material at the beginning of sewing by means of the needle thread clamp device, as well as at the end of sewing by means of the thread trimmer which is provided with a shorter-thread remaining function. This means that manual thread nipping both at the beginning and at the end of sewing is no longer required, thereby helping reduce operator fatigue.

Thanks to the adoption of a 2.7- fold hook, the frequency of bobbin thread changing is reduced and workability is improved.

| Model name | LU-2810VA70BBSZ/X73235 | LU-2828V-7 | LU-2860V-7 | ||||

|---|---|---|---|---|---|---|---|

| Type | 1-needle, Unison-feed, Lockstitch Sewing System | 1-needle, Unison-feed, Lockstitch Sewing System (Shorter – thread remaining type) | 2-needle, Unison-feed, Lockstitch Sewing System | ||||

| Max. sewing speed | 3,500sti/min* | ||||||

| Max. stitch length | 9.0mm | 12.0mm | |||||

| Presser foot | 20mm | ||||||

| Alternating vertical movement (DL) | 9.0mm | ||||||

| Needle thread tension | 0~200 | ||||||

| Presser foot pressure | 0~200 | ||||||

| Hook | Vertical axis 2.0 fold-capacity hook | Vertical axis 2.7 fold-capacity hook | Vertical axis 2.0 fold-capacity hook | ||||

| Needle | 135×35 Nm160 (#23), Nm125~Nm180 (#20~#24) | 134×35 Nm140 (#22), Nm125~180 (#20~#24) | 134×35 Nm160 (#23), Nm125~200 (#20~#25) | ||||

| Thread | 60/ 3~20/ 3 (#30~#5) | 60/ 3~10/ 3 (#30~#0) | |||||

| Machine head weight | 61Kg | 66Kg | 68Kg | ||||

*sti/min is the abbreviation for “stitches per minute”